Marine Applications We Support

- Propulsion & Power: lube oil pressure protection, jacket water, fuel pressure monitoring, auxiliary generators

- Hydraulic Systems: steering gear, stabilizers, hatch covers, cranes & winches, capstans

- Fluid Handling: ballast/bilge pumping, fire-main pressure, freshwater makers, cooling seawater

- Safety & Monitoring: compressor cut-in/cut-out, filter clog indication (ΔP), alarm panels, PLC/SCADA

- Deck & Port Equipment: davits, windlasses, hose handling reels, loading arms

Barksdale Product Categories for Marine

Pressure Switches (Mechanical & Electronic)

Protect engines, pumps, and gearboxes with field-adjustable, high-accuracy switches.

- Ranges: vacuum to 10,000+ psi (0–700 bar)

- Contacts: SPDT / DPDT, gold or silver contacts for low/high current

- Enclosures: compact, sealed, or heavy-duty for vibration and mist

- Benefits: fast response, reliable cut-in/cut-out, long service life

Pressure Transducers & Transmitters

Rugged sensors for continuous pressure monitoring and trending.

- Outputs: 4–20 mA, 0–10 V, ratiometric; optional diagnostic features

- Materials: stainless steel wetted parts; options for seawater compatibility

- Use cases: fuel rails, hydraulic manifolds, fire main, jacket water, air compressors

Temperature Switches & Sensors

Maintain safe operating temps in cooling circuits, bearings, and gear oil.

- Types: bimetal, RTD, NTC/PT100/PT1000 options

- Set points: fixed or adjustable

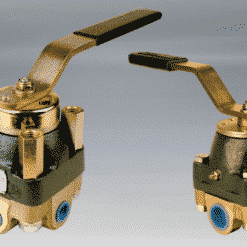

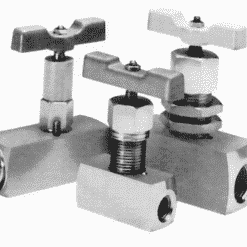

Valves (Directional, Relief, Shutoff)

Built for hydraulic and pneumatic control in demanding duty cycles.

- Styles: needle, relief, check, and specialty valves

- Advantages: low leakage, stable cracking pressures, robust sealing

Not sure which model is right? See our or send us your spec sheet.

Why Marine Teams Choose Us for Barksdale

- Application engineering: We help set ranges, contact logic, and output scaling correctly the first time.

- Compliance-minded: We’ll align with your project documentation and testing needs. (Share your class requirements and we’ll match suitable options.)

- Inventory & kitting: Stocking programs for common set points and thread types; labeled kits per vessel or work package.

- Lifecycle support: Cross-references for legacy parts and planned spares for dry-dock periods.

Technical Capabilities (At-a-Glance)

- Pressure ranges: Vacuum to 700 bar (10,000+ psi)

- Process connections: NPT, BSPP/BSPT, SAE, DIN, and custom adapters

- Electrical: flying leads, DIN, M12, conduit, terminal blocks

- Accuracy: from ±0.25% FSO (sensor-dependent)

- Environmental: IP-rated housings, shock & vibration-resistant designs

- Media: fuel, lube oil, seawater, air, glycol, hydraulics (confirm compatibility)

Note: Always verify the latest datasheet for exact ratings and approvals for your selected model.

Example Marine Use Cases

1) Fire Main & General Service Pumps

- Goal: Maintain pressure above alarm set point under dynamic load

- Solution: Electronic pressure switch with 4–20 mA transmitter to the PLC plus hardwired alarm contact

- Outcome: Faster diagnostics, reduced nuisance trips

2) Steering Gear Hydraulic Power Unit

- Goal: Reliable high/low pressure switching for dual-pump systems

- Solution: Dual-set-point mechanical switches with SPDT contacts and vibration-resistant housings

- Outcome: Simplified wiring and robust redundancy

3) Engine Room Lube Oil Protection

- Goal: Protect engines during start-up and transient conditions

- Solution: Compact pressure switch with tight differential and N/C logic for fail-safe alarms

- Outcome: Stable cut-out and improved safety compliance

Get Help Specifying Your Barksdale Part

Have a drawing, P&ID, or old tag plate? We can cross-reference and supply a drop-in equivalent.

What to send us

- Pressure range (normal & alarm), units, and desired set point(s)

- Process connection (thread type/size), media, and temperature range

- Electrical interface (contact type or analog output)

- Environmental considerations (IP rating, vibration, enclosure style)

- Any class or documentation requirements

Request a quote: (713) 683-6826 • sales@WilsherCo.com

FAQs

Can you match our existing switch set points?

Yes. Provide your set point, reset point (differential), and media details—we’ll factory-set and label each unit.

Do you provide documentation for class approvals?

We can supply manufacturer datasheets and test reports for your selected products and align with your project submittal package. Share your class requirements and we’ll advise suitable options.

Barksdale Temperature Switch MT1H-H251-12-A

2 × $665.00

Barksdale Temperature Switch MT1H-H251-12-A

2 × $665.00 Barksdale Valve 9021-MC-A

1 × $300.00

Barksdale Valve 9021-MC-A

1 × $300.00